Renewable materials are the basis for

green solutions

Chemical solvents fulfil many roles. They are used to make printer inks and nail polish, for example, and have many other every day applications.

The problem is that most of them are not particularly environmentally friendly. That’s why we have developed a greener alternative, CyreneTM. It has the advantage of being more environmentally friendly and safer to use than conventional solvents. Unlike petroleum-based solvents, CyreneTM is made from renewable waste cellulose obtained from Pinus radiata.

Pinus radiata is the Latin name for a pine tree with remarkable characteristics. It is also called the Monterey pine. The Pinus radiata is a very popular agricultural crop that is also widely used for the reforestation of fallow land. The reason for this is simple: Pinus radiata grows faster than many other tree species and can reach its full size in just 35 years.

Find out more about Cyrene™What do you think?

How much does a Pinus radiata grow in height per year?

Answer

Given the right conditions, the pine can reach its full size of 50 meters in around 35 years. This means that it grows on average about 140 centimeters per year.

Actual growth

140 cm

Less consumption, more power

Bendable screens

Ultra-thin displays that can be rolled up? Thanks to so-called OLEDs (organic light emitting diodes), display screens can now even be bent and folded.

Today, OLEDs with remarkably vibrant colors can be found in smart phones and TVs. OLED displays offer several advantages:

Thin displays: Each OLED pixel lights up by itself, so no backlighting is needed. This makes OLED displays lighter.

Low energy consumption: OLEDs only consume electricity when they are active. The strength of the electric current regulates the brightness.

High contrast: OLED displays show a supreme contrast, because pixels work individually and can be turned off completely to deliver a true black.

We are one of the leading manufacturers of OLED materials. An important goal is also to produce them in a way that uses resources efficiently. OLED materials can be processed efficiently, because our customers collect unused materials in the production process and send them back to us. We then reprocess these materials so that they can be used again for display production. This process design is environmentally friendly.

Fight against microplastics

Small endangerers

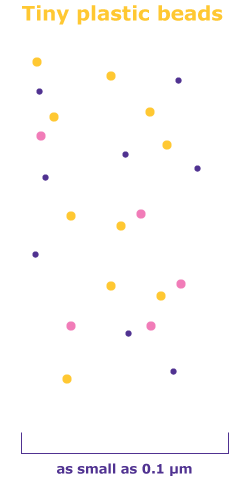

Small in size, but they can do a great deal of damage: tiny plastic beads that are used in many cosmetic products such as lotions, make-up, toothpastes and soaps.

In personal care products, microplastic is often used because of its safe and effective exfoliating properties, and in cover products it is used as a filler. But too many microplastics particles end up in the sea – which is a threat to maritime ecosystems.

Did you know?

The tiny plastic beads do not dissolve in water. Because they are as small as 0.1 μm in size, wastewater treatment plants cannot filter them out, and so the microplastic passes unhindered into rivers, lakes and oceans, where it is eaten by fish and other creatures. It takes about 100 years for the microbeads to biodegrade.

We offer environmentally friendly alternatives:

RonaFlair® Flawless

RonaFlair® Flawless is a so-called “functional filler”, which helps to cover skin irregularities. It is based on natural minerals and is a suitable alternative to plastic microbeads. The filler is used in skin care and color cosmetic formulations such as powder-based makeup products.

RonaFlair® LDP White

The filler RonaFlair® LDP White consists of white ceramic microspheres, which are provided with environmentally friendly mineral coatings. The spherical particles make skin feel supple. Areas of application for the filler also include powder-based products.

Safe and environmentally friendly packaging

Less is more

Every year, we send large quantities of products to our customers in specially developed packaging. We set high quality requirements for the packaging material, because our products should reach their destination safely. At the same time, we work to ensure that our packaging places as little burden on the environment as possible.

How do we achieve this? By setting ourselves ambitious goals, for example is in the field of life science. By 2022, we would like to achieve four key goals:

Shrink = Reduce the amount of packaging by

- reducing packaging-to-product weight ratio

- investigating bulk packaging solutions

- reducing air space in shipping boxes

Secure = Ensure that packaging materials based on wood and paper fibers do not contribute to deforestation by

- demonstrating responsible sourcing

- increasing the use of certified materials

- increasing recycled content

Switch = Increase sustainability of plastic used in packaging applications by

- using plastic with lower environmental impacts

- increasing the use of recycled and renewable content

- reducing the use of expanded polystyrene (EPS)

Save = Maximize the recycling of our packaging by

- introducing new standards to optimize recyclability of new packaging

- eliminating use of packaging materials that are not compatible with recycling

- introducing guidelines for recycling or disposal for all packaging types

Click to explore

Worldwide network

Innovating together

We want to develop quality products that are more sustainable than traditional solutions. To achieve this, we work together with many bright minds around the world. Here is just a small selection of our partners:

York (United Kingdom):

In cooperation with the Green Chemistry Centre of Excellence and Circa™, we are commercializing the environmentally friendly solvent, Cyrene™.

California and Massachusetts (United States):

In a partnership with the NGOs My Green Lab and Beyond Benign, we published a tutorial on how to integrate the topic of “green chemistry” into university courses on organic chemistry.

California (United States):

In partnership with the University of California, Berkeley Center for Green Chemistry, we are working on improving our quantitative green chemistry analysis tool DOZN™ for practical application in the field and on investigating safer alternatives to additive manufacturing feedstock formulas for 3D printing.

Plouguerneau (France):

Together with the French company Agrimer, we have launched RonaCare®RenouMer - a natural skincare product derived from marine algae.

Massachusetts (United States):

Together with Triumvirate Environmental, we are recycling over 3,000 tons of plastic waste collected from our Biopharma manufacturing customers.

Stuttgart (Germany):

In cooperation with the Institute for Lightweight Structures and Conceptual Design (ILEK), we are working on the integration of our dynamic liquid crystal window technology eyrise™ into load-bearing structures, enveloping systems and interior design for the built environment of tomorrow.

Read more here.